This text will be overwritten by jQuery

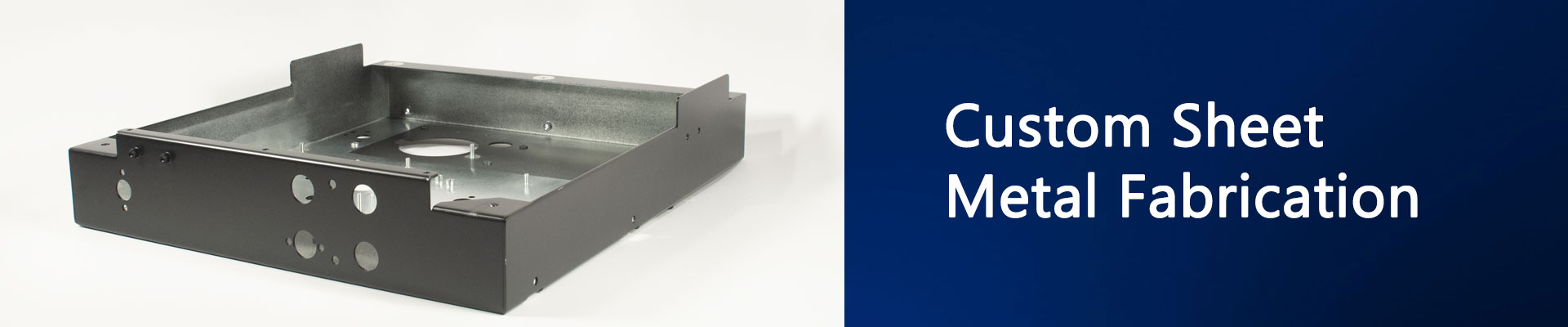

Sparton is a family owned and operated AS9100 and ISO9001 certified Contract Manufacturer committed to superior quality and customer service. We are a trusted high end producer of components and assemblies for all of your Metal Fabrication needs in various commercial industries, as well as Defense and Aerospace. We have been excelling in the custom manufacturing business since 1972, and have been evolving since our modest beginning. We excel at Precision Sheet Metal Fabrication, Heavy Gage Metal Fabrication, and weldments from sheet metal, thick gage, machined parts, and tube frames.

Sparton has offered precision sheet metal parts and sub-assemblies since 1984. We serve a vast array of industries including:

Our goal is to surpass your company's visual quality standards on a consistent basis, shipment after shipment. All of our punched and laser cut edges are deburred to remove any sharp edges or heavy punch marks.

Sparton's Metal Fabrication division is equipped with the latest technology to competitively operate in today’s environment with the ability for Laser cutting, punching, & robotic welding. With a variety of state-of-the-art machines, we are equipped to perform your most complicated sheet metal, heavy gage fabrication, and weldments. We can laser cut up to 1” Steel plate and punch up to ¼” sheet stock.

(2) CAM Seats, Metalsoft's Fabriwin

(4) CAD Seats, SolidWorks 3D Solid Modeling

(1) 4000W Fiber IPG Lasercube

(1) Mitsubishi LVP 3015, 4000 watts, with full FMS (Inventory Tower and fully Automated Loading and Unloading.

Amada Pega Punch presses: (1) Amada 358 with Auto load/unload and (1) Amada 345.

(6) Lincoln C300 for GMAW (MIG) Welding, (6) Thermal Arc Arcmaster 300 ACDC for GTAW (TIG) Welding, (1) 150 KVA Sciacki Deep Throat Spot welder, (1) 100 KVA Sciacki Deep Throat Spot welder

HG8025 8’ (2) with off line programming, 8 feet, Toyokoki HYB 8 feet, Di-acro 4 feet

(2) Motoman ArcWorld GMAW multi-table robotic welding cells for production steel & SST.

5 hardware insertion machines, equipped with modular autofeed systems, capable of all your faster needs (i.e. self-clinching & rivets).

Our amphibian enclosures meet the harsh NEMA 6P standards required to withstand prolonged submersion in floodwaters. Read More

Fill out our form to request a quote or request more information.